Kanazawa’s Kaga Yuzen: hand-painted kimono silks to dye for

If Japan’s 47 prefectures were to put on a fashion show, there’s no doubt that Ishikawa would make a splash. The traditional territory of the Kaga samurai domain is still renowned for its gorgeous gold leaf, a product of its legendary wealth. Equally beautiful but less familiar to foreign visitors is the silk dyeing technique known as Kaga Yuzen, seen on elegantly understated, painstakingly hand-dyed kimono and other handcrafted fabrics.

caption: Connected to its workshop, Kagayuzen Maida’s showroom is all about tradition and innovation

Handcrafted beauty

As Hitoshi Maida holds a bolt of silk under the light, he trains an expert eye on its stenciled pattern, and begins to paint on the silk. Maida is a yuzen craftsman at Kagayuzen Maida, a Kaga Yuzen dyeing workshop in Kanazawa. He and his father, Kenji Maida, have produced a range of elegant and detailed fabric designs for kimono and beyond. They have also created Kaga Yuzen scarves, kerchiefs, business card cases, table runners, furoshiki wrapping cloths and framed fabrics, all lovingly painted and dyed in the Kaga Yuzen tradition.

Their award-winning work has appeared at the Ishikawa Prefectural Music Hall, at Uniqlo in Florida, in luxury Japanese resorts, and even on the uniforms of Shinkansen bullet train staff.

caption: Maida demonstrates the interior painting technique on a bolt of silk

“From initial designs to the finished kimono, we do everything by hand here,” says the younger Maida. “Another distinguishing feature of Kaga Yuzen is the beauty of nature showcased in the designs.”

The history of Kaga Yuzen dyeing stretches back about 500 years, when the silk-production region of Kaga was known for its monochrome umezome dyeing, which used the interior of plum tree trunks for their distinctive shade of red. In 1712, Miyazaki Yuzen (1654–1736), a renowned fan designer, moved to Kaga to work for the Tarodaya dyeing house and began to dye clothing.

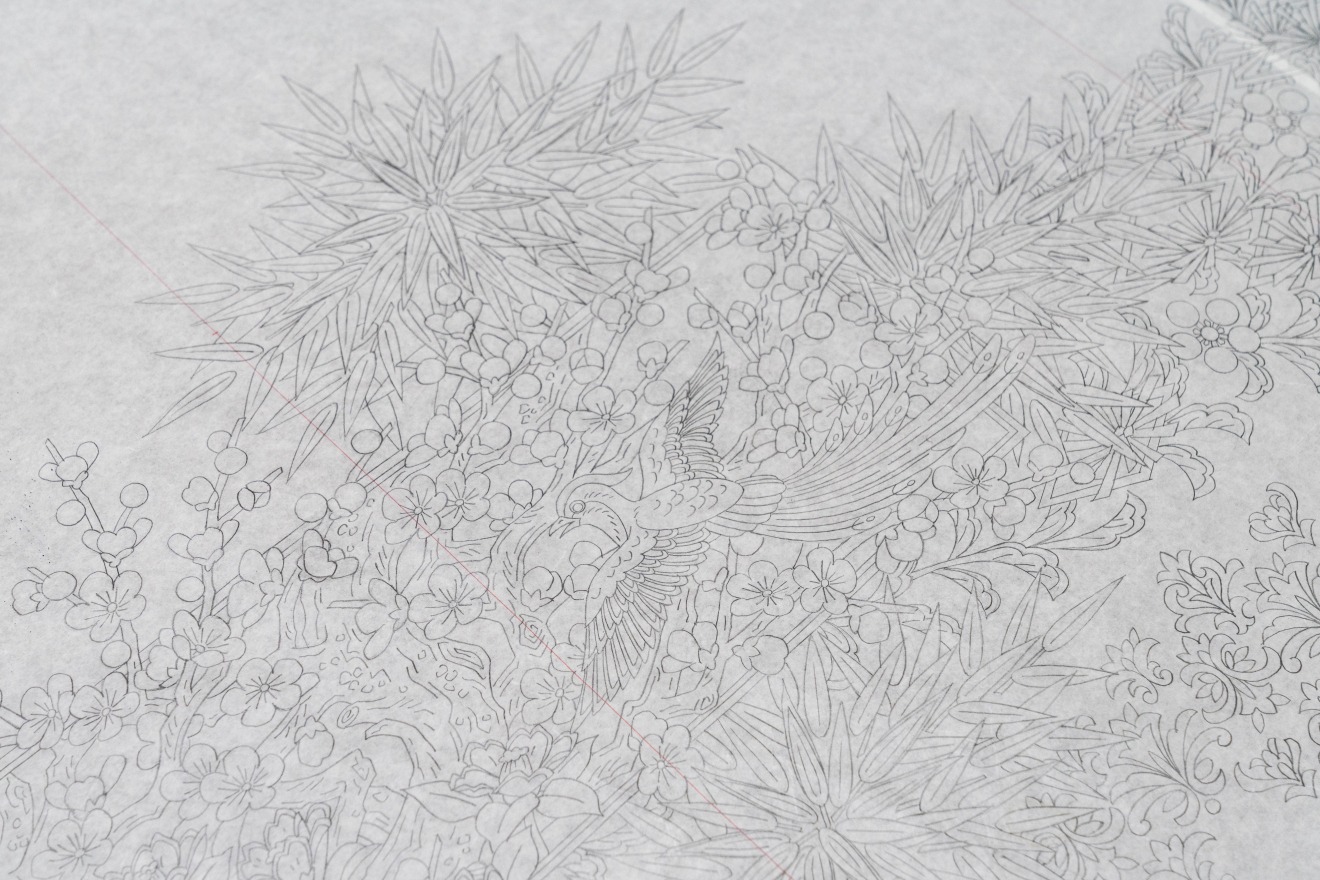

caption: The Kaga Yuzen dyeing process begins with tracings of pencil sketches onto undyed silk

What makes Kaga Yuzen special? For starters, it uses five basic colors, known as Kaga gosai: indigo, crimson, ocher, dark green and purple. The subject matter of the designs tends to have a seasonal motif such as plants, landscapes and birds, with an approach that emphasizes realism and fine detail—for instance, leaves are sometimes depicted with holes in them, suggesting they’ve been fodder for insects.

caption: Some of the Kaga gosai dyes at Kagayuzen Maida

Kaga Yuzen can be distinguished from Kyo Yuzen, or Yuzen dyeing from Kyoto, by its lack of tie-dying, embroidery, gold leaf and other typical Kyoto features. Kaga, Kyoto and Tokyo Yuzen make up the main traditional centers of silk dyeing in Japan.

caption: Kaga Yuzen silks are dyed in the five basic colors, known as Kaga gosai

Steeped in color—and tradition

To create Kaga Yuzen silk, fabrics go through 15 steps with the highly skilled artisans at Kagayuzen Maida. First, a design is sketched on paper. It’s then placed between a light source and a glass surface on which a bolt of 12-meter-long, undyed fabric is laid, allowing the artisans to trace the design onto the fabric with the juice of an Asiatic dayflower known as aobana. The juice dissolves later when rinsed in water.

caption: Maida demonstrates the background dyeing technique, done with a broad brush as the silk is stretched out

Next, to prevent dyes from running, itome-nori glutinous rice flour paste is applied to the tracing before the areas inside the outlines are painted in, a crucial step that will determine the beauty and quality of the finished product. After a steaming step to fix the colors, the painted parts are covered with paste to protect them during the background dyeing, done with a broad brush.

caption: Mr Araki, pictured in Ishikawa’s Asanogawa River, is one of the few living Kaga Yuzen artisans who remembers the old fashioned technique of rinsing dyed kimono fabrics in rivers. Here he is explaining and demonstrating the technique to the younger generations in hope that the technique doesn’t completely fade away

Finally, the fabric is dried on racks and subjected to finishing steps including dyeing corrections and adjusting the texture and width of the fabric with steam. It’s then ready to be made into kimono or a number of other items that Maida and his design team can dream up, from wall hangings and hand towels to jewelry and other accessories.

“I’m always thinking of the future of kimono, new designs and new challenges that I can undertake as a Kaga Yuzen craftsman,” says Maida. “I also want to continue applying the techniques of Kaga Yuzen to new products and go beyond kimono.”

He also welcomes visitors to his Kaga Yuzen workshop. To reserve a space on one of the workshops please make a reservation via a travel agency through the Ichigo Ichie website operated by Kanazawa City Tourism Association.

https://visitkanazawa.jp/en/ichigo-ichie

caption: These delicately crafted earrings are another example of the evolving applications for Kaga Yuzen dyeing